-

Llámenos +8613585169988

-

Envíanos un correo electrónico machine@cnznep.com

This machine is used to make paper shopping bags with flat handles inline (handles folded inside the bag or upright when coming out) fully automatically.

Tipo de mango :

flat handles (overfolded and upright)ZD-FN380QT/550QT Automatic Paper Bag Making Machine With Twisted Rope/flat Handles And Flap

This machine is specially designed to make paper shopping bags with flap and twisted rope handles inline automatically. The handles will be delivered to the main machine after being produced by the handle making unit, and being cut and pasted to the paper. This machine can form the paper bag in one process from the plain or pre-printed reel paper, window cut and waste suction for flap, gluing & pasting, easy tearing line perforation, pre-cut at the rope position, gluing for handle patch and pasting, side gluing, tube forming & cutting, bottom creasing & gluing and forming to bags collection.

The whole machine is in the control of servo motors (made in Japan) to ensure the machine running speed and stability, also the time for sizes adjustment will be saved. It is featured in high precision and stability, simple maintenance and high efficiency. Thus it is an ideal equipment for printing houses and paper bag manufacturers.

Product Details

| Model | ZD-FN380QT | ZD-FN550QT |

| Roll paper width | 580-1270mm | 630-1730 mm |

| Max. dia. of roll paper | φ1500 mm | φ1500 mm |

| Insidedia of paperroll | φ76 mm | φ76 mm |

| Paper gram | 60/80-150 g/㎡ | 80/90-150 g/㎡ |

| Finished bag width | 200-380 mm | 220-550 mm |

| Paper tube length | (230+舌口)-(655mm含舌口&绳高) | (380+舌口)-(770mm含舌口&绳高) |

| Bag bottom width | 75-240 mm | 80-300 mm |

| Flap height | 30-80 mm | 30-80 mm |

| Releasing paper width | 15-35 mm | 15-35 mm |

| Flap paper gram | 50-100 g/㎡ | 50-100 g/㎡ |

| Max production speed | 120 bags/min | 110 bags/min |

| Total power | 380V 3P4L 56KW | 380V 3P4L 56KW |

| Weight | 27000 KG | 29000 KG |

| Overall dimensions | 15800*6900*3400 mm | 17600*7200*3500 mm |

Product Video

Product Unit Introduction:

|

FEEDING UNIT The roll paper fixed on the air expanding mandrel can be fed by swing arm which is equipped with lifting hydraulic system. With an alarm function, the feeding unit will sound alarm when there is no paper feeding. Improved surface smoothness of the paper during the feeding is achieved due to the web guide and uniform tension control. Paper rolls can be easily changed by pressing a button. |

| JAPANESE SERVO MOTORS SYSTEM

The machine is controlled by Mitsubishi servo motors. Bags lengths and widths can be adjusted automatically. |

|

|

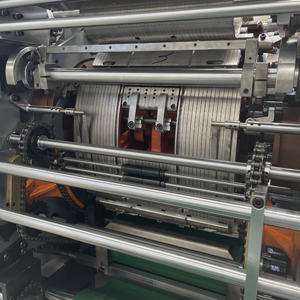

BAG'S BOTTOM FOLDING UNIT The drum for bottom folding, is with air-suction system, suitable for wide gram range of the raw paper. |

|

BAG FORMING UNIT Form the paper with patches and side glue into the tube; and cut into separate pieces based on the settings. Afterwards, these separate tubes will be sent to the drum to open the four corners, then bottom gluing, sealing and form the square shape consequently. |

|

|

BAG COLLECTING UNIT Compress the bags and output the finished bags. The number of paper bags processed can be displayed by the automatic collection and counting system. |

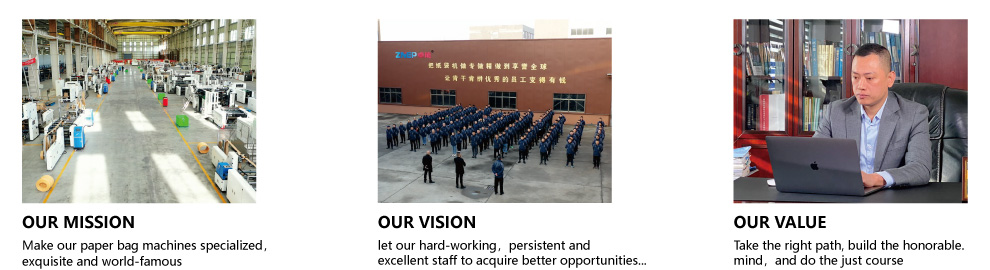

Brief Introduction

This machine is specially designed to make paper shopping bags with handles inline fully automatically. The handles will be delivered to the main machine after being produced by the handle making unit, and being cut and pasted to the paper. This machine can form the paper bag in one process from the paper roll, handle patching, side gluing, tube forming & cutting, bottom creasing & gluing and forming to bags collection in the control of servo motors (Mitsubishi brand, imported from Japan) to ensure the high precision and stability, simple maintenance and high efficiency. Thus it is an ideal equipment for printing houses and paper bag manufacturers.

Details Images

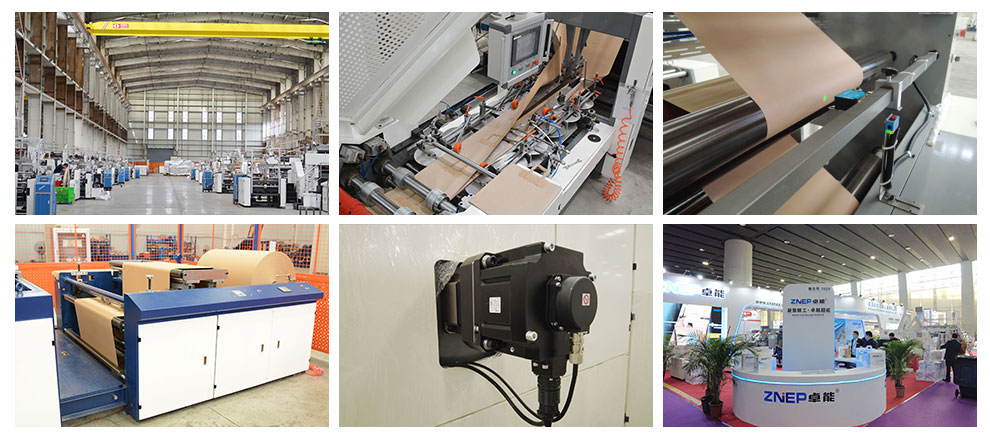

Company Profile

About us

Our company was founded in 1997, and initially engaged in the producton and sales of precision components: Since 2002, we have been engaged in the research, development, manufacturing and sales of automatic pocket and wallet style evelope machines. In 2008 due to the compay's development needs, we moved to Gaochun Develooment Zone in Naning and established Naning Zono Machine Equipment Co, Ltd, specializing in the research, development, manufacturing, and sales of fully automatic paper bag machines. Since its estabishment, the compay has always implemented the business philosoohy of "based on quality in the market, winning customers by service, creating brands with reputation, and leading development with innovaton". We closely adhere to the internal management of the company and stricly implement ISO9001 quality system standards and CE safety certficaton, in recent years, we have sucessively obtained and been recognized as a high-tech enterprise, intelligent packaging engineering technology center, enterprise technology center, enterprise industrial design center, China's high-quality products, Jiangsu qualty and nteorty 3A eve drand erterorse. and neary 40 invention patents. Our company aways adheres to the oeore-orented deve ooment an osomh actvely everaoes the power of the eam, unites more outstanding people to participate in the development process of the enterprise. and allows truly talented people to maxmize their value. and grow and develop together with the enterprise. We firmly beleve that Zono company will become a leader in the paper bag machine manutacturing industry in the near future. This is our goal and our great & glorious task.

Certifications

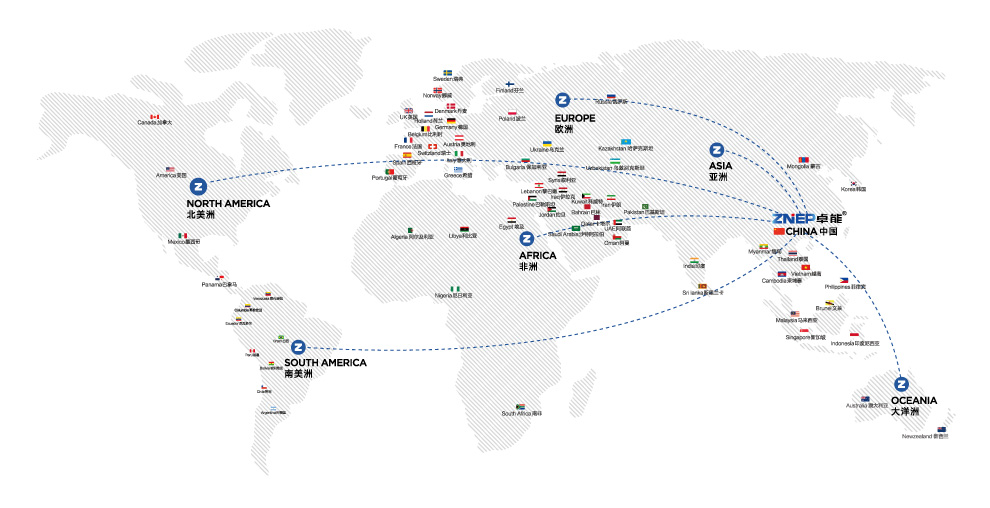

User world distribution map

Our users are located around the world

We have dients worldwide, for example,South-East Asians such as South Korea (Daegu, Paju-si), Vietnam, Cambodia, Philippines, India (Mumbai, New Delhi), Indonesia, Pakistan; European countries such as Spain (Madrid, Tenerife), Portugal, Finland, Ukraine, Turkey (lstanbul, Konya); North America such as USA, Canada (Toronto, Trois-rivers, Winnipeg); South America such as Uruguay, Chile, Guatemala; Mid East such as Palestine, Syria; African countries such as Tanzania (Arusha, Moshi), Kenya (Nairobi, Nakuru, Malindi, Algeria, Cote D'Ivoire, Morocco (Tangier, Casablanca). Domestic cooperative customers such as some listed enterprises, and well-known enterprises in the industing packaging and printing.

ETIQUETAS :